Project Background

A Philippine customer in the industrial fluid handling sector requires continuous solid-liquid separation of media within pipelines in their production process to protect downstream equipment and ensure stable system operation. Because the production line requires 24-hour continuous operation, traditional stand-alone filtration equipment must be shut down for filter basket cleaning, which has long been a key bottleneck affecting production efficiency and stability.

The customer clearly stated three core requirements for this project:

The filtration system must support continuous operation, with no interruption of pipeline flow during cleaning;

The equipment should possess excellent corrosion resistance and structural strength to withstand common industrial media;

The operation process must be simple and efficient, facilitating quick switchover and maintenance by on-site personnel.

To address the industry pain point of "shutdown cleaning," the client sought a filtration solution specifically designed for continuous operation.

Technical Solution

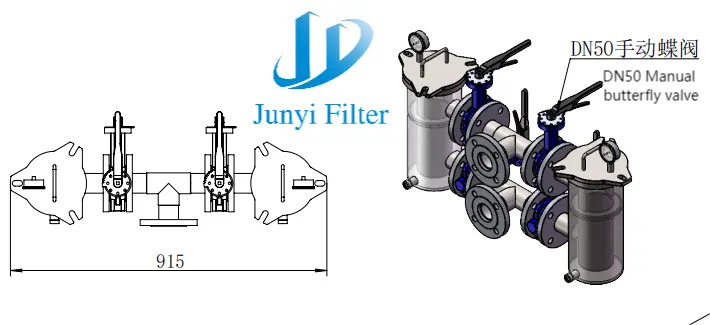

Based on the customer's operating conditions and goals, Shanghai Junyi Filtration Equipment Co., Ltd. customized the JYBF50-304 double basket filter for them. It adopts a double parallel structure and valve switching mechanism to achieve continuous filtration without shutting down the system.

The core design of this system includes:

1. Double Parallel Structure:

Equipped with two independent stainless steel filter baskets, the flow path is switched manually via butterfly valves. When one set of filter baskets requires cleaning, the medium automatically switches to the other set for continuous filtration without stopping production.

2. 304 Stainless Steel Material:

The entire machine body and filter baskets are made of 304 stainless steel, possessing excellent corrosion resistance and mechanical strength, suitable for conventional industrial fluid environments.

3. Precise Matching to Piping Systems:

The equipment adopts a DN50 flange connection, with a compact structure that can be directly connected to the customer's existing pipelines without additional modifications.

4. Standardized Precision Configuration:

The filter baskets have a filtration accuracy of 100 μm, effectively intercepting common particulate impurities in pipelines and protecting downstream equipment.

Before leaving the factory, each unit undergoes valve switching flexibility, sealing performance, and flow path switching continuity testing to ensure stable operation and the achievement of the functional goals of "cleaning without stopping and filtration without interruption."

Customer Feedback

After the equipment was ready for shipment and passed factory testing, the customer confirmed that the dual basket filter fully met the technical requirements of their continuous production operation.

The customer stated that the solution successfully resolved previous production interruptions caused by filter basket cleaning, enabling the pipeline system to maintain stable operation. Simultaneously, the equipment's ease of operation and durable structure reduced daily maintenance difficulty and improved overall production reliability.

This collaboration further validates Junyi's technical adaptability and customized delivery capabilities in continuous fluid filtration applications, providing a reliable guarantee for the customer's long-term stable operation.

Junyi Copyright © 2025 ALL rights reserved