Our company has recently completed the preparation of a fully automatic candle filter for shipment to a client in Mexico. Designed specifically for fine carbon powder filtration, the system delivers a high processing capacity of 5 tons per hour. With its superior solid-liquid separation efficiency and precise process adaptability, it sets a new benchmark for filtration performance in the agricultural processing sector.

Project Overview & Technical Configuration

The supplied equipment features a filtration area of 10 m², dedicated to treating blackwater generated during avocado processing (solid content: 3–5%, pH≈7, maximum temperature: 60 °C).

Constructed from food-grade SS304 stainless steel, the system utilizes petal-shaped candle elements (φ90×1400 mm) combined with PET3927 filter cloth, ensuring excellent sealing and corrosion resistance.

The unit is equipped with 25 filter elements, providing a total solids capacity of approximately 150 L. A centrifugal pump delivers a feed pressure of 0.5–0.6 MPa, enabling high-pressure filtration and efficient solid-liquid separation with clear filtrate and stable performance.

Advantages & Automation Features

Compared to traditional filter presses, the fully automatic candle filter offers several key advantages:

--Compact footprint and superior sealing performance

--High degree of automation with minimal manual operation

--Extended service life and resistance to high temperatures

--Wide application range across food, chemical, pharmaceutical, and wastewater industries

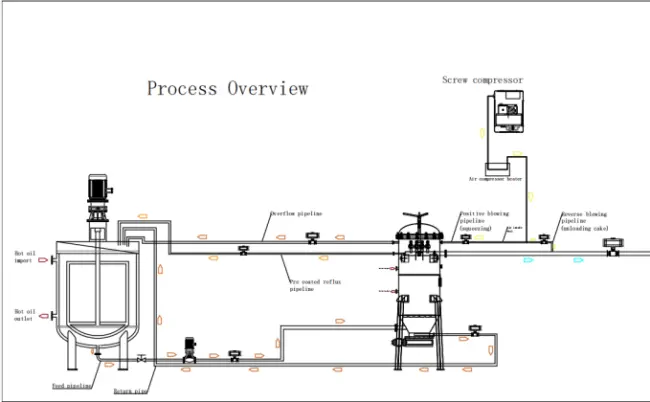

The system operates automatically through a full “filtration–cleaning–discharge” cycle, comprising five key stages:

1. Initialization: The system automatically checks sealing integrity and establishes a closed filtration channel.

2. Pressurized Filtration: Feed liquid is pumped under pressure into the filter housing for solid-liquid separation.

3. Automatic Discharge Trigger: Upon reaching a preset pressure differential, the system switches to discharge mode.

4. Back-Blow Cleaning: Compressed air or cleaning liquid reverses flow to remove the filter cake.

5. Discharge & Reset: Solids are automatically discharged, and the system resets for the next cycle.

In addition, a backwash cleaning function is included to maintain long-term stability and filtration efficiency. Cleaning is recommended weekly or biweekly to ensure optimal performance.

The equipment has been fully tested and is ready for shipment to Mexico under CIF terms.

Looking ahead, our company will continue to focus on efficiency, safety, and intelligent automation, delivering customized filtration solutions for diverse liquid processing applications and helping global clients enhance production quality and operational performance.

Junyi Copyright © 2025 ALL rights reserved